DIN 6798 A/J Serrated Lock Washers—With Internal/External Teeth

Short Description:

Min.Order Quantity:1000PCS

PACKAGING:BAG/BOX WITH PALLET

PORT:TIANJIN/QINGDAO/SHANGHAI/NINGBO

DELIVERY:5-30DAYS ON QTY

PAYMENT:T/T/LC

Supply Ability:500 TON PER MONTH

Product Detail

Product Tags

Product Description:

| Product name | Serrated Lock Washer |

| Size | M1.7-31 |

| Material | Steel/Stainless steel |

| Surface treatment | Zinc |

| Standard | DIN/ISO |

| Certificate | ISO 9001 |

| Sample | Free Samples |

The serrated washer is used for small parts to act as a spring. Its size is similar to the fastening screws of three-dimensional plate stamping parts used with it.

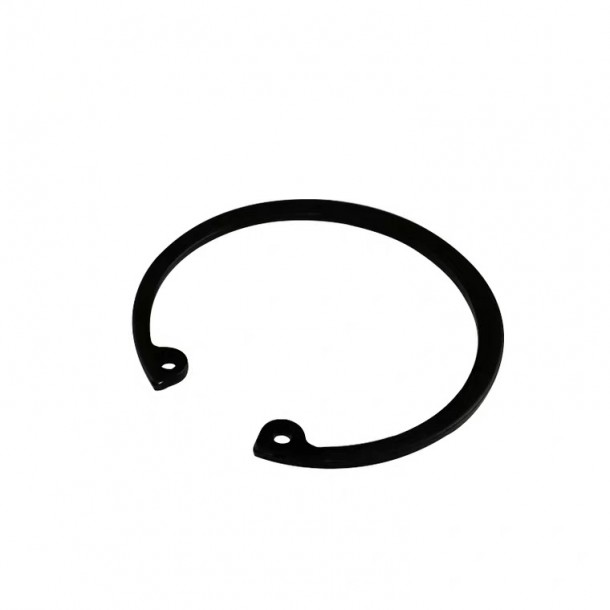

The serrated lock washer is used in conjunction with a nut to be mounted on a bolt, and its function is similar to a spring pad, which can play a role of locking and preventing loosening.Serrated lock washers are divided into internal serrated lock washers and external serrated lock washers.Although they are lock washers, they are still quite different.

Difference between internal serrated lock washers and external serrated lock washers

①Difference in appearance

Although the two gaskets have similar names, their shapes differ greatly.The internal serrated lock washer, as the name suggests, the washer has serrations inside, and the external serrated lock washer has serrations outside the washer.

② Functional differenceInternal toothed lock washers are used under the head of smaller screw heads. Internal toothed lock washers are mostly used in mechanical assemblies to fasten anti-vibration seals and are stable.

Product advantages:

- Precision Machining

☆ Measure and process using precision machine tools and measuring tools under strictly controlled environmental conditions.

- High-quality

☆ With long life, low heat generation, high hardness, high rigidity, low noise, high wear resistance and other characteristics.

- Cost-effective

☆ The use of high-quality carbon steel steel, after precision processing and forming, greatly improves the user experience.

Surface treatment:

- ZINC

☆ Electro-galvanizing is a traditional metal coating treatment technology that provides basic corrosion resistance to metal surfaces. The main advantages are good solderability and suitable contact resistance. Due to its good lubrication properties, cadmium plating is commonly used in aviation, aerospace, marine, and radio and electronic products. The plating layer protects the steel substrate from both mechanical and chemical protection, so its corrosion resistance is much better than zinc plating.

OUR PACKAGE:

1. 25 kg bags or 50kg bags.

2. bags with pallet.

3. 25 kg cartons or cartons with pallet.

4. Packing as customers' request