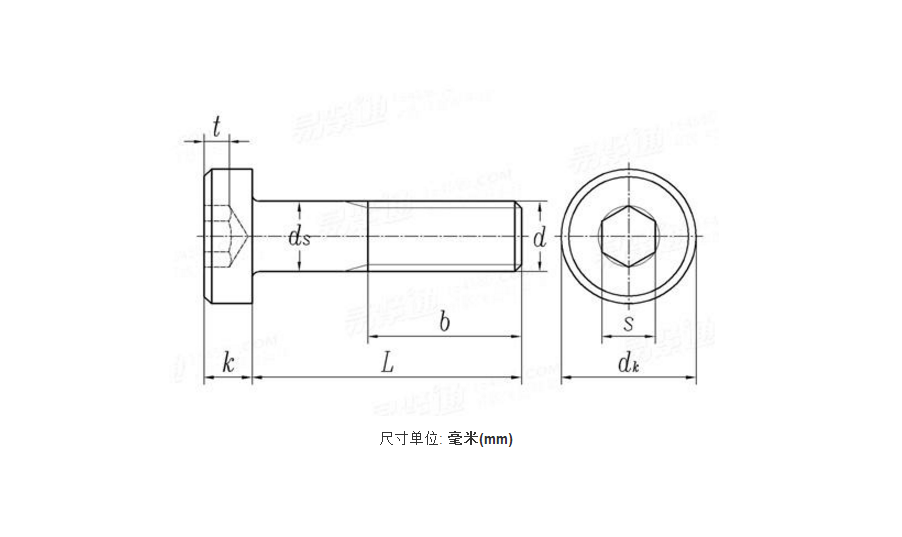

Din 7984 hex socket thin head cap bolt

Short Description:

Min.Order Quantity:2TONS

PACKAGING:BAG/BOX WITH PALLET

PORT:TIANJIN/QINGDAO/SHANGHAI/NINGBO

DELIVERY:5-30DAYS ON QTY

PAYMENT:T/T/LC

Supply Ability:500 TON PER MONTH

Product Detail

Product Tags

Product Description:

| Product name | hex socket thin head cap bolt |

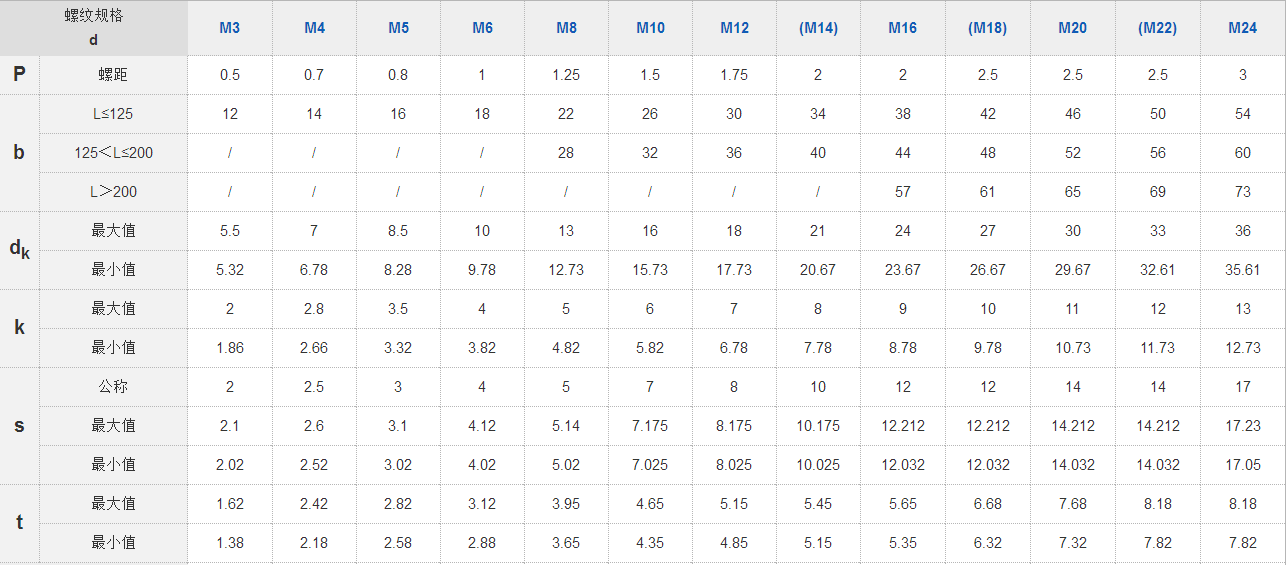

| Size | M3-24 |

| Length | 5-100mm or as required |

| Grade | 4.8/8.8/10.9/12.9 |

| Material | Steel/35k/45/40Cr/35Crmo |

| Surface treatment | Plain/Black/Zinc/HDG |

| Standard | DIN/ISO |

| Certificate | ISO 9001 |

| Sample | Free Samples |

Usage:

DIN7984 thin head hexagon socket screws are a type of hole-type screws. Thin head hexagon socket screws are generally used in machine tools, chemical equipment, water pumps, ships, power equipment and other places. Hexagon screws are more used in export equipment in China.

Carbon steel thin-headed hexagon socket head screws are generally grades 8.8 and 12.9.

Grade 12.9 thin-headed hexagon socket head screws are generally not plated in order to avoid hydrogen embrittlement and cracks or fractures of the products after plating.

Product advantages:

- Precision Machining

☆ Measure and process using precision machine tools and measuring tools under strictly controlled environmental conditions.

- High-quality carbon steel(35#/45#)

☆ With long life, low heat generation, high hardness, high rigidity, low noise, high wear resistance and other characteristics.

- Cost-effective

☆ The use of high-quality carbon steel steel, after precision processing and forming, greatly improves the user experience.

Surface treatment:

- BLACK

☆ Black is a common method for metal heat treatment. The principle is to make an oxide film on the metal surface to isolate the air and achieve rust prevention. Blackening is a common method for metal heat treatment. The principle is to make an oxide film on the metal surface to isolate the air and achieve rust prevention.

- ZINC

☆ Electro-galvanizing is a traditional metal coating treatment technology that provides basic corrosion resistance to metal surfaces. The main advantages are good solderability and suitable contact resistance. Due to its good lubrication properties, cadmium plating is commonly used in aviation, aerospace, marine, and radio and electronic products. The plating layer protects the steel substrate from both mechanical and chemical protection, so its corrosion resistance is much better than zinc plating.

- HDG

☆ The main advantages are good solderability and suitable contact resistance. Due to its good lubrication properties, cadmium plating is commonly used in aviation, aerospace, marine, and radio and electronic products. The plating layer protects the steel substrate from both mechanical and chemical protection, so its corrosion resistance is much better than zinc plating. Hot-dip zinc has good corrosion resistance, sacrificial protection for steel substrates, high weather resistance, and resistance to salt water erosion. It is suitable for chemical plants, refineries and coastal and offshore operating platforms.

OUR PACKAGE:

1. 25 kg bags or 50kg bags.

2. bags with pallet.

3. 25 kg cartons or cartons with pallet.

4. Packing as customers' request