Lag Screw

Short Description:

EXW PRICE : 720USD-910USD/TON

Min.Order Quantity:2TONS

PACKAGING:BAG/BOX WITH PALLET

PORT:TIANJIN/QINGDAO/SHANGHAI/NINGBO

DELIVERY:5-30DAYS ON QTY

PAYMENT:T/T/LC

Supply Ability:500 TON PER MONTH

Product Detail

Product Tags

Lag Screws: A Comprehensive Guide

Introduction

Lag screws, also known as coach screws or wood screws, are robust fasteners designed to provide strong, secure connections in wood and other materials. Their unique design, featuring a coarse thread and a sharp point, allows for easy driving into wood and other materials, making them a popular choice for various construction and woodworking applications.

Features and Benefits

- Strong and Secure: The coarse thread and sharp point of lag screws create a strong, secure connection that can withstand significant loads.

- Versatility: Lag screws are suitable for a wide range of applications, from light-duty woodworking to heavy-duty construction.

- Durability: Made from high-quality materials, lag screws offer excellent durability and resistance to corrosion.

Types and Materials

While there are numerous variations, lag screws generally fall into two main categories:

- Wood Screws: These screws are specifically designed for use in wood and have a coarser thread than machine screws.

- Machine Screws: These screws have a finer thread and are often used in metal applications but can also be used in wood.

Common materials for lag screws include:

- Carbon Steel: A cost-effective option that is often galvanized or plated for corrosion resistance.

- Stainless Steel: Offers superior corrosion resistance and is ideal for outdoor or marine applications.

- Brass: Provides a decorative finish and good electrical conductivity.

Applications

Lag screws are widely used in:

- Woodworking: Securing beams, posts, and other structural elements.

- Construction: Building decks, framing, and other wooden structures.

- Furniture Making: Assembling furniture and cabinets.

- Industrial Applications: For general fastening and assembly tasks.

Installation

- Pre-drilling: It’s essential to pre-drill a pilot hole before driving in a lag screw to prevent splitting the wood.

- Choosing the Right Size: Select a lag screw that is appropriate for the thickness of the material being joined and the load it will need to support.

- Tightening: Use a wrench or socket wrench to tighten the lag screw securely, ensuring a strong connection.

Why Choose Lag Screws?

Lag screws offer a combination of strength, versatility, and ease of installation, making them an ideal choice for many fastening applications. Their ability to create strong, secure connections in wood makes them a staple in the construction and woodworking industries.

Ready to order your lag screws? Contact our sales team at vikki@cyfastener.com for a quote or to discuss your specific requirements. We offer a wide range of lag screws to meet your exact needs.

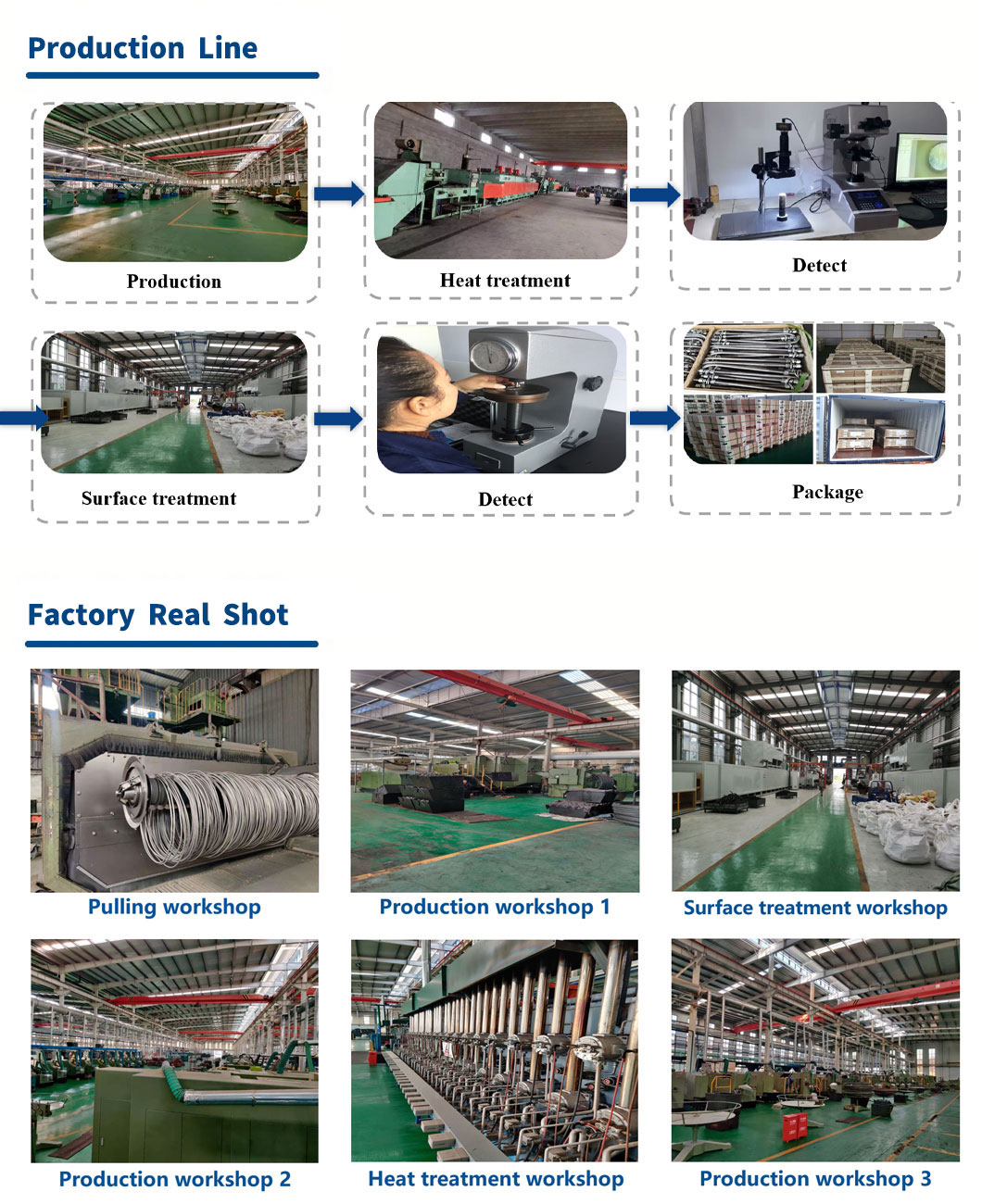

Hebei Chengyi Engineering Materials Co., Ltd. has 23 years of manufacturing experience and with advanced equipment, senior professional and technical personnel, and advanced management system, it has developed as one of the larger local standard parts manufacturers, strong technical force, enjoys high erreputation in there industry. The company accumulated many years of marketing knowledge and management experience, effective management norms, in strict accordance with national standards, the production of various kinds of fasteners and special parts.

Mainly supply seismic bracing,hex bolt, nut, flange bolt, carriage bolt, T bolt, threaded rod, hexagon socket head cap screw, anchor bolt, U-bolt, and more products.

Hebei Chengyi Engineering Materials Co., Ltd. aims at “good faith operation, mutual benefit and win-win”.

OUR PACKAGE:

1. 25 kg bags or 50kg bags.

2. bags with pallet.

3. 25 kg cartons or cartons with pallet.

4. Packing as customers’ request