In the process of stamping and producing metal molds, the phenomenon of poor stamping must be analyzed in detail and effective countermeasures must be taken.

The causes and countermeasures of common stamping defects in production are analyzed as follows, for the reference of mold maintenance personnel:

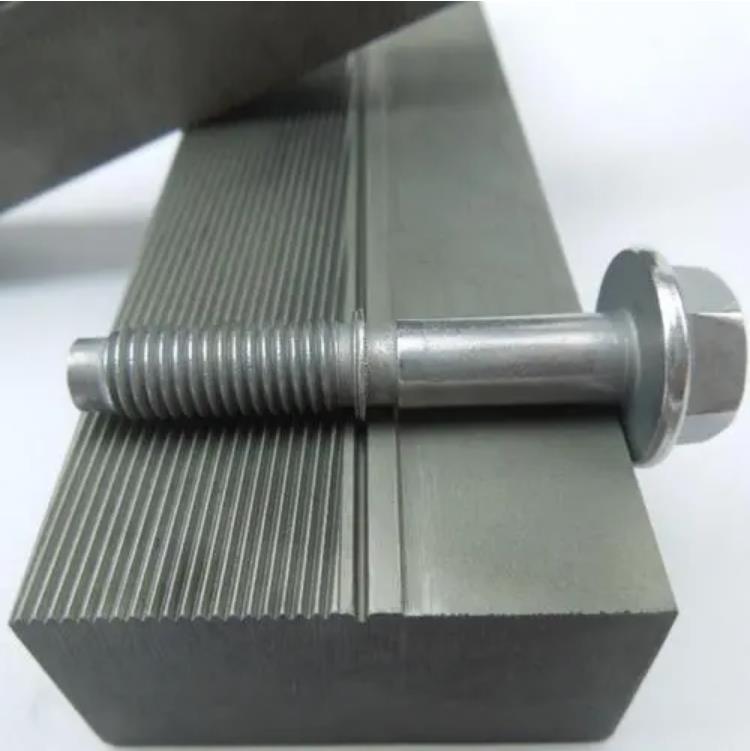

1. Burrs on stampings.

(1) Reason: The knife edge is worn out. b. If the gap is too large, the effect will not be obvious after sharpening the knife without cutting firewood by mistake. c. Chipped edges. d. The clearance moves up and down unreasonably or becomes loose. e. The mold is misaligned up and down. .

(2) Countermeasures: a. Research cutting-edge technology. b. Control the processing accuracy of the metal mold or modify the design clearance. C. Training knife edge. d. Adjust the blanking gap to confirm the wear of the template hole or the processing accuracy of the formed parts. e. Replace the guide mold or reassemble the mold. .

2. To crumble and crush.

(1) Reason: The gap of one is too big. b. Unreasonable shipping charges. c. Punching oil drops too fast, oil sticks. d. The mold does not demagnetize. e. The punch is worn, and chips are squeezed and attached to the punch. f. The punch is too short and the length of the insert is insufficient. g. The material is relatively hard, and the punching shape is simple. h. Emergency measures. .

(2) Countermeasures: a. Control the machining accuracy of the metal mold or modify the design clearance. b. When the mold is sent to the proper position, it should be repaired and cleaned in time. c. Control the amount of punched oil droplets, or change the oil type to reduce the viscosity. d. It must be demagnetized after training (more attention should be paid when punching iron materials). e. Study the edge of the punch. f. Adjust the length of the punch blade into the die. g. Change the material, modify the design. The punch blade enters the end face, ejects or repairs with a bevel or arc (note the direction). Reduce the bonding area between the end face of the punch blade and the chips. h. Reduce the sharpness of the die-cutting edge, reduce the amount of training on the die-cutting edge, increase the roughness (coating) of the straight edge of the die-cutting, and use a vacuum cleaner to absorb waste. Reduce punching speed and slow chip jumping. .

3. The chip is blocked.

(1) Cause: One leak hole is too small. b. The leakage hole is too large, and the waste rolls over. c. The knife edge is worn and the burrs are large. d. Punching oil drop too fast, oil sticky. e. The surface of the straight blade of the concave die is rough, and the powder chips are sintered and attached to the blade. f. The material is soft. g. Emergency measures. .

(2) Countermeasures: a. Modify the leakage hole. b. Modify the leak hole. c. The edge of the blade is repaired. d. Control the amount of dripping oil and change the type of oil. e. Surface treatment, polishing, pay attention to reduce surface roughness during processing. Change the material, modify the blanking gap. g. Repair the slope or arc on the end face of the punch blade (pay attention to the direction), and blow air to the blanking hole of the backing plate with a vacuum cleaner. .

4. The size change of blanking deviation.

(1) Reason: The edge of the metal mold is worn and burrs are generated (the shape is too large and the inner hole is too small). b. The design size and clearance are improper, and the machining accuracy is poor. c. There is a deviation between the punch and the mold insert at the lower material level, and the gap is uneven. d. The guide pin is worn and the diameter of the guide pin is insufficient. e. The guide rod is worn. f. The feeding distance is not adjusted properly, and the feeder is pressed loose. g. Improper adjustment of mold clamping height. h. The press-in position of the discharge insert is worn, and there is no press-in (forced press-in) function (the material is pulled over to cause a small punch). I unloaded the blade pressed too deep and the punch was too big. j. Changes in the mechanical properties of stamping materials (unstable strength and elongation). k. When punching, the punching force pulls on the material, causing dimensional changes. .

(2) Countermeasures: a. Research cutting-edge technology. b. Modify the design and control the machining accuracy. c. Adjust its position accuracy and blanking gap. d. Replace the guide pin. e. Replace the guide post and guide sleeve. f. Readjust the feeder. g. Adjust the mold clamping height. h. Grind or replace the unloading insert, increase the strong pressure function, and adjust the pressing material. i. Reduce pressure depth. j. Replace raw materials and control the quality of raw materials. k. The end face of the punching blade is trimmed into a bevel or arc (note the direction) to improve the stress during punching. Where permitted, the unloading element is located on the unloading blade with guiding function. .

5. Card material.

(1) Reasons: a. Improper adjustment of the feeding distance, and the feeder is pressed and loosened. b. Feed distance changes during production. C. The delivery machine is faulty. d. The material is bent, the width exceeds the tolerance range, and the burrs are large. e. The stamping of the die is not normal, causing the first bend. f. Insufficient hole diameter of the guide material, the upper die pulls the material. g. The bent or torn position cannot fall off smoothly. h. The stripping function of the material guide plate is not set properly, and the material tape falls on the belt. My material is thinning and warping during feeding. j. The mold is not installed properly, and there is a large deviation from the verticality of the feeder. .

(2) Countermeasures: a. Readjust b. Readjust c. Adjust and maintain. d. Replace raw materials and control the quality of incoming materials. e. Eliminate the first bend of the strap. f. Study punching, guide hole convex and concave dies. g. Adjust the ejection spring force, etc. h. Modify the material guide plate, and install the reverse material belt on the belt. I add upper and lower pressing materials between the feeder and the mold, and increase the safety switch of the upper and lower pressing materials. j. Reinstall the mold.

Post time: Jan-13-2023