Socket Cap Screw Manufacturers - Carbon Eye Bolt DIN 444 – Yateng

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Socket Cap Screw Manufacturers - Carbon Eye Bolt DIN 444 – Yateng Detail:

Product Description:

| Product name | Eye bolt |

| Size | M6-64 |

| Length | 20-300mm or as required |

| Grade | 4.8/8.8/10.9/12.9 |

| Material | Steel/35k/45/40Cr/35Crmo |

| Surface treatment | Plain/Black/Zinc/HDG |

| Standard | DIN/ISO |

| Certificate | ISO 9001 |

| Sample | Free Samples |

Usage:

Application items: filter type self-rescuer, gas detection instrument, dust mask, mining raincoat, mine blaster, application details: joint bolts are widely used: low temperature and high pressure valves, pressure pipelines, fluid engineering, petroleum drilling and production equipment, Oilfield equipment and other fields are often used in disassembly and connection occasions or tools such as the valve industry, folding bicycles, baby carriages. Due to the convenient and fast use of live bolts, the use of supporting bolts plays a role of connection and fastening. Wide and wide.

Product advantages:

- Precision Machining

☆ Measure and process using precision machine tools and measuring tools under strictly controlled environmental conditions.

- High-quality carbon steel(35#/45#)

☆ With long life, low heat generation, high hardness, high rigidity, low noise, high wear resistance and other characteristics.

- Cost-effective

☆ The use of high-quality carbon steel steel, after precision processing and forming, greatly improves the user experience.

Surface treatment:

- BLACK

☆ Black is a common method for metal heat treatment. The principle is to make an oxide film on the metal surface to isolate the air and achieve rust prevention. Blackening is a common method for metal heat treatment. The principle is to make an oxide film on the metal surface to isolate the air and achieve rust prevention.

- ZINC

☆ Electro-galvanizing is a traditional metal coating treatment technology that provides basic corrosion resistance to metal surfaces. The main advantages are good solderability and suitable contact resistance. Due to its good lubrication properties, cadmium plating is commonly used in aviation, aerospace, marine, and radio and electronic products. The plating layer protects the steel substrate from both mechanical and chemical protection, so its corrosion resistance is much better than zinc plating.

- HDG

☆ The main advantages are good solderability and suitable contact resistance. Due to its good lubrication properties, cadmium plating is commonly used in aviation, aerospace, marine, and radio and electronic products. The plating layer protects the steel substrate from both mechanical and chemical protection, so its corrosion resistance is much better than zinc plating. Hot-dip zinc has good corrosion resistance, sacrificial protection for steel substrates, high weather resistance, and resistance to salt water erosion. It is suitable for chemical plants, refineries and coastal and offshore operating platforms.

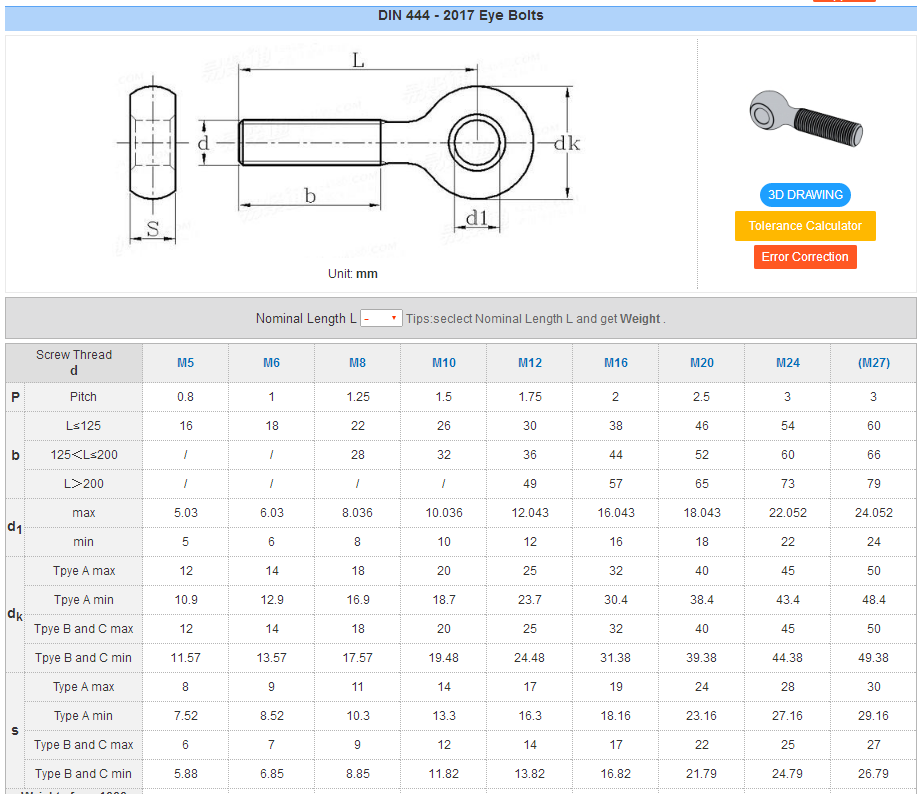

Parameter Of Product:

OUR PACKAGE:

1. 25 kg bags or 50kg bags.

2. bags with pallet.

3. 25 kg cartons or cartons with pallet.

4. Packing as customers’ request

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for Socket Cap Screw Manufacturers - Carbon Eye Bolt DIN 444 – Yateng , The product will supply to all over the world, such as: panama, United States, Jersey, We have a large share in global market. Our company has strong economic strength and offers excellent sale service. We have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

Products categories

-

Din 913 Manufacturers - DIN 929 Carbon Steel/S...

-

China Wholesale Hot Dip Galvanized Hex Nut Manu...

-

China Star Lock Washer - Full Threaded Hex Bol...

-

Free sample for Socket Head Bolt - Carriage Bo...

-

Professional China Fasteners - ISO 7380 Hexago...

-

Excellent quality Iso 4762 - High Quality Fact...